Turntable Induction Hardening Machine for High-Speed Batch Production

Unlike linear or single-station hardening systems that limit concurrent processing, the turntable design of this machine features a multi-position turntable (typically 4–8 stations) that enables simultaneous execution of key workflows: workpiece loading/unloading, pre-heating, induction hardening, and post-hardening cooling. This sequential yet parallel operation drastically reduces cycle times, making it ideal for high-volume production of parts like fasteners, small gears, valve stems, and precision pins. Each station is equipped with specialized fixtures tailored to secure different component geometries, ensuring stability during rotation and preventing deformation — even for irregularly shaped parts.

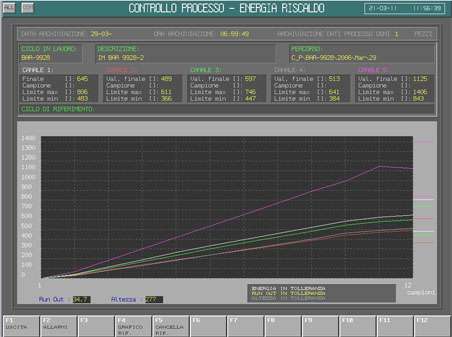

Its intuitive HMI (Human-Machine Interface) allows operators to program and store process parameters for multiple part types, enabling quick changeovers between batches — critical for manufacturers handling diverse product lines. Whether you’re scaling up production of standard parts or managing flexible batch runs of custom components, the Turntable Induction Hardening Machine is a future-ready investment that balances efficiency, precision, and adaptability to elevate your manufacturing capabilities.

- ZT 500

- ZT 800

- ZT 1500

- 8-position turntable

- One or two pieces at one cycle

- Full length hardening

- Maximum workpiece length: 500 mm

- Maximum workpiece diameter: 80 mm

- Vertical scanning length up to 600 mm

- Scanning speed up to 8.5 m/min

- Adjustable rotation speed

- Tailstock

- Automatic front doors

- Automatic “empty table” function

- Recommended: 100 – 150 kW

- PLC + Industrial computer control system

- 8-position turntable

- One or two pieces at one cycle

- Maximum workpiece length: 800 mm

- Maximum workpiece diameter: 100 mm

- Vertical scanning length up to 950 mm

- Scanning speed up to 12 m/min

- Adjustable rotation speed

- Tailstock

- Automatic front doors

- Automatic “empty table” function

- Recommended: 150 – 200 kW

- PLC + Industrial computer control system

- 3-position turntable

- Workpiece length up to 1000 mm

- Workpiece diameter up to 500 mm

- Vertical scanning length up to 1300 mm

- Adjustable rotation speed up to 200 rpm

- Tailstock

- Power supply: 800 kW, 3-level switchable frequency

- PLC + Industrial computer control system

- Industry 4.0 standard

- User-friendly HMI (Human-Machine Interface)

Power Supply for Induction Heating

- High Digital Advantages:Digital control replaces over 70% of traditional electronic hardware. The software enabling command transmission, parameter regulation, operational control, and system protection delivers higher precision and more sophisticated functions.

- User-Friendly O&M Design:The integrated keyboard supports rapid and accurate diagnostics, covering the operating status of all electronic components and cooling systems. A series resonant circuits enable automatic tuning and eliminating the need for manual adjustment when replacing inductors.

- High Adaptability & High Power:With a quality factor (Q-Factor) exceeding 2, it offers strong flexibility, supporting various inductors (both single-coil and multi-coil configurations) while delivering maximum output power.

Core Specifications:

- Output power ranging from 10 kW to 500 kW

- Operating frequency spanning from 100 Hz to 100 kHz

Optional Configurations:

- Dual-output design, supporting manual or automatic switching functionality

- Frequency switching module (high/medium/low), enabling a standard operating frequency reduction of up to 50%

Standard Equipment for All Models:

- Supply transformer

- Chopper voltage regulator integrated with IGBT transistors

Control Systems

- User-Friendly HMI:The SD focuses on creating intuitive human-machine interface (HMI) software, tailored for unskilled operators to ensure easy operation.

- Safe Operation:Throughout the design process, the SD prioritizes and guarantees safe operating conditions at all times.

Hardware Options

- PLC + Operator Panel, suitable for simple applications

- PLC + Axes Control Unit + Industrial PC, suitable for more complex and advanced machines

- PLC + CNC, suitable for machines with specific functions or multi-axis interpolation capabilities

Software Options:

- Programmable logic (PLC) software, always accompanied by comments

- Human-machine interface (HMI) softwares running on the Windows OS for industrial computers are designed according to machine types with dedicated softwares

- CNC-based applications utilize the ISO language

Control Levels

| Basic | Heating energy control and quenching shower flow control |

| Middle | Heating energy control, oscillation frequency, quenching shower flow, and quenchant temperature control |

| Advanced | Heating energy control, voltage control, current control, frequency control, quenching shower flow control, quenchant temperature control, and inductor collision detection |

| Custom | The number of control channels is selected based on the safety level requirements of the process and product. |

Cooling Systems

GSC Cooling System

A typical GSC system consists of the following components:

- Stainless steel tank equipped with a minimum level sensor

- Water-to-water heat exchanger in stainless steel

- Main cooling pump made of stainless steel

- Magnetic flow sensors with on-board adjustable alarm set points

Optional Components

- Automatic shutdown function to reduce industrial water consumption

- Automatic antifreeze system and automatic anti-condensation system

- Automatic water conductivity detection system

- Additional pump for high-pressure inductor feeding

GLT Cooling System

The CLT systems, designed based on power supply specifications and process type, serve as the optimal solution for achieving proper workpiece quenching.

A typical CLT system comprises the following components:

- Stainless steel tank equipped with a level sensor

- Stainless steel cooling pump

- Water-to-water heat exchanger in stainless steel

- Stainless steel shower pump

- Automatic workpiece temperature stabilization system

- Automatic filtration system

Optional Components

- Additional magnetic filtration section

- Automatic pre-heating system based on a weekly schedule

- Automatic system for removing suspended oil

- Automatic quenchant mixture type selection system (applicable when two or more CLT systems are in use)

- Automatic shutdown function to reduce industrial water consumption

Get in touch right now for solutions meeting your specific needs!