Disc Part CNC Hardening Machine for Gears, Saw Blades & Disc Components

Unlike general-purpose hardening machines that may struggle with the unique geometry of disc components (e.g., flat surfaces, inner/outer rims, and thin cross-sections), this CNC-driven system is tailored explicitly for disc processing. It features programmable motion controls that adjust the induction coil’s position, heating intensity, and dwell time with micron-level precision, ensuring uniform hardening across the entire disc surface — even for parts with complex grooves or asymmetrical designs. The machine’s specialized clamping system securely holds discs without causing deformation, while its integrated cooling module precisely regulates post-hardening temperature, preventing cracks and preserving the part’s structural integrity.

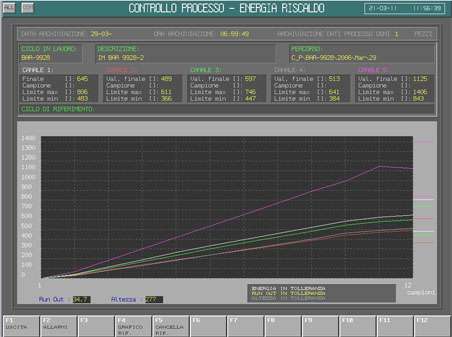

Its intuitive HMI (Human-Machine Interface) allows operators to program and store process parameters for multiple part types, enabling quick changeovers between batches — critical for manufacturers handling diverse product lines. Whether you’re manufacturing high-volume automotive components or low-batch precision industrial discs, this machine is a purpose-built investment that elevates your disc part quality, reduces rework, and enhances production efficiency.

- ZD 1500

- Three-axis control: rotation + vertical + horizontal

- Workpiece diameter up to 1500mm

- Workpiece height up to 900 mm

- Max horizontal travel: 800 mm

- Max vertical travel: 1100 mm

- Retractable tailstock with automatic self centering chuck

- Automatic tracking system for maintaining a constant gap between workpiece and sensors

- Automatic reset for tooth by tooth quenching

- Recommended power: 150KW

- Camera for easy monitoring of the quenching area

- Quick equipment installation

- CNC system

- User-friendly HMI (Human-Machine Interface)

This machine can also be used as a standard vertical scanning hardening machine.

Power Supply for Induction Heating

- High Digital Advantages:Digital control replaces over 70% of traditional electronic hardware. The software enabling command transmission, parameter regulation, operational control, and system protection delivers higher precision and more sophisticated functions.

- User-Friendly O&M Design:The integrated keyboard supports rapid and accurate diagnostics, covering the operating status of all electronic components and cooling systems. A series resonant circuits enable automatic tuning and eliminating the need for manual adjustment when replacing inductors.

- High Adaptability & High Power:With a quality factor (Q-Factor) exceeding 2, it offers strong flexibility, supporting various inductors (both single-coil and multi-coil configurations) while delivering maximum output power.

Core Specifications:

- Output power ranging from 10 kW to 500 kW

- Operating frequency spanning from 100 Hz to 100 kHz

Optional Configurations:

- Dual-output design, supporting manual or automatic switching functionality

- Frequency switching module (high/medium/low), enabling a standard operating frequency reduction of up to 50%

Standard Equipment for All Models:

- Supply transformer

- Chopper voltage regulator integrated with IGBT transistors

Control Systems

- User-Friendly HMI:The SD focuses on creating intuitive human-machine interface (HMI) software, tailored for unskilled operators to ensure easy operation.

- Safe Operation:Throughout the design process, the SD prioritizes and guarantees safe operating conditions at all times.

Hardware Options

- PLC + Operator Panel, suitable for simple applications

- PLC + Axes Control Unit + Industrial PC, suitable for more complex and advanced machines

- PLC + CNC, suitable for machines with specific functions or multi-axis interpolation capabilities

Software Options:

- Programmable logic (PLC) software, always accompanied by comments

- Human-machine interface (HMI) softwares running on the Windows OS for industrial computers are designed according to machine types with dedicated softwares

- CNC-based applications utilize the ISO language

Control Levels

| Basic | Heating energy control and quenching shower flow control |

| Middle | Heating energy control, oscillation frequency, quenching shower flow, and quenchant temperature control |

| Advanced | Heating energy control, voltage control, current control, frequency control, quenching shower flow control, quenchant temperature control, and inductor collision detection |

| Custom | The number of control channels is selected based on the safety level requirements of the process and product. |

Cooling Systems

GSC Cooling System

A typical GSC system consists of the following components:

- Stainless steel tank equipped with a minimum level sensor

- Water-to-water heat exchanger in stainless steel

- Main cooling pump made of stainless steel

- Magnetic flow sensors with on-board adjustable alarm set points

Optional Components

- Automatic shutdown function to reduce industrial water consumption

- Automatic antifreeze system and automatic anti-condensation system

- Automatic water conductivity detection system

- Additional pump for high-pressure inductor feeding

GLT Cooling System

The CLT systems, designed based on power supply specifications and process type, serve as the optimal solution for achieving proper workpiece quenching.

A typical CLT system comprises the following components:

- Stainless steel tank equipped with a level sensor

- Stainless steel cooling pump

- Water-to-water heat exchanger in stainless steel

- Stainless steel shower pump

- Automatic workpiece temperature stabilization system

- Automatic filtration system

Optional Components

- Additional magnetic filtration section

- Automatic pre-heating system based on a weekly schedule

- Automatic system for removing suspended oil

- Automatic quenchant mixture type selection system (applicable when two or more CLT systems are in use)

- Automatic shutdown function to reduce industrial water consumption

Get in touch right now for solutions meeting your specific needs!